Automatic Machines for IG Units

Insulated Glass Unit (IGU): An IGU consists of two or more glass panes separated by a spacer and sealed together to create a single unit. It often contains air or inert gas between the panes for thermal and acoustic insulation.

Use: Widely employed in windows, doors, and facades for homes, offices, and commercial buildings to enhance energy efficiency.

Benefit: Reduces heat loss or gain, minimizes noise, lowers energy costs, and improves indoor comfort.

Automatic Machines for IGUs: These machines are designed to automate the manufacturing process of IGUs, such as glass cutting, spacer application, sealing, and gas filling.

Use: Utilized in factories to streamline IGU production with precision and speed.

Benefit: Increases production efficiency, ensures consistent quality, reduces labor costs, and shortens production time.

glass beveling and polishing machines

Our glass edge beveling and polishing machine is a top-tier solution designed to refine and enhance the edges of glass and mirrors with exceptional precision and quality. This advanced equipment ensures that edges are beveled to perfection, creating smooth, polished finishes that elevate the aesthetic appeal and functional utility of the glass or mirror.

With our state-of-the-art beveling and polishing machine, we offer edge-beveled sizes tailored to meet your specific requirements. This enables the use of glass or mirrors without the need for a frame, providing a sleek, modern, and frameless design that complements any space. Whether for architectural applications or decorative purposes, our machine delivers unparalleled results, ensuring the glass or mirror is not only visually striking but also structurally robust and ready to shine in any setting.

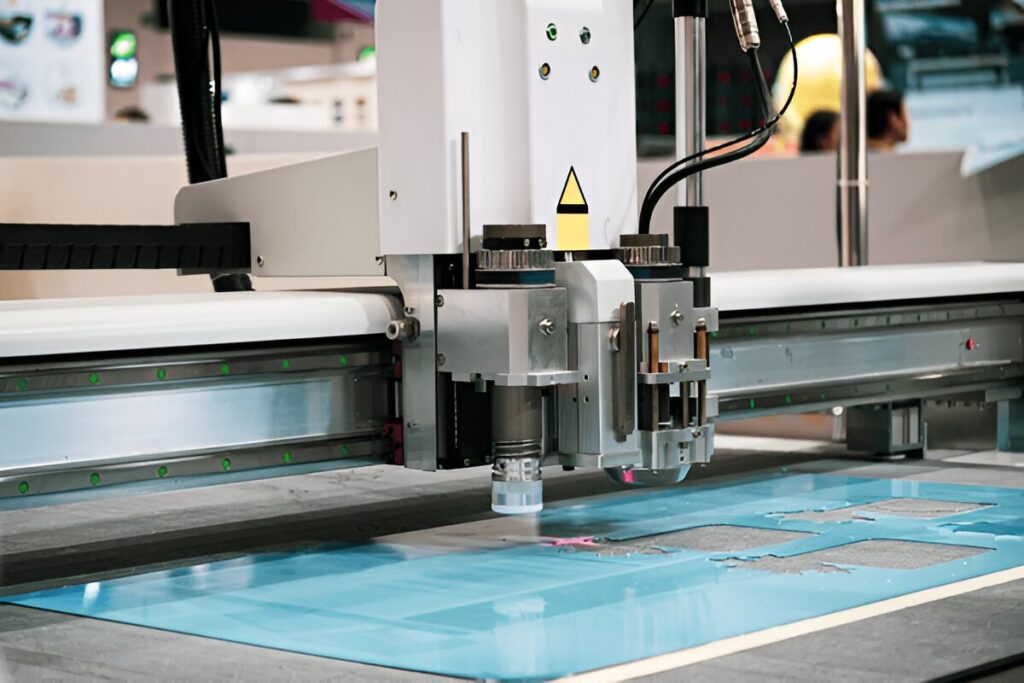

CNC CUTTING MACHING

Canadian Architectural Glass (CAG) integrates CNC glass cutting machines into their production processes to achieve superior precision and quality. These machines allow CAG to handle complex cutting patterns and large-scale projects efficiently, catering to the evolving needs of their clients.

CNC technology enables CAG to produce custom glass solutions for architectural, residential, and commercial applications. With its ability to deliver intricate designs and consistent results, it supports CAG’s commitment to innovation and excellence in the glass industry.

CNC SHAPE & POLISH

CNC (Computer Numerical Control) glass shaping and polishing is a cutting-edge process that uses advanced machinery to create precise and intricate designs on glass surfaces. This technology allows for the production of custom shapes, smooth edges, and polished finishes with unparalleled accuracy. CNC machines are capable of handling complex patterns, making them ideal for architectural, decorative, and functional glass applications.

Precision Glass Cutting: Using CNC technology, we deliver highly accurate and intricate glass cutting services for any design requirement.

Custom Glass Shaping: Our machines can craft unique glass shapes tailored to your needs, whether for decorative or functional applications.

Edge Polishing: We ensure that every glass edge is polished to perfection, offering a smooth, flawless finish.

GLASS LAMINATION MACHINE

Our Laminating Machine (EVA “Ethylene Vinyl Acetate” Lamination) is a state-of-the-art solution designed for producing customized glass laminates with unparalleled precision and versatility.

Having an in-house laminating facility allows us to transcend standard glass thickness limitations, combining multiple layers of glass to achieve any required thickness for a given project.

This capability provides unmatched flexibility, enabling innovative applications and bespoke solutions. Our advanced technology goes beyond laminating clear and tinted glass—it also supports the lamination of intricate mesh patterns and creative shape designs, ensuring exceptional aesthetic and functional results tailored to every architectural need.

glass sandblasting or etching

Glass sandblasting is a technique that uses fine abrasive particles propelled at high pressure to frost or carve designs onto glass surfaces. With our top-of-the-line equipment and machinery, combined with decades of expertise, Canadian Architectural Glass delivers precision and craftsmanship. We have the capability to achieve any shape or design, ensuring custom, high-quality results for every project

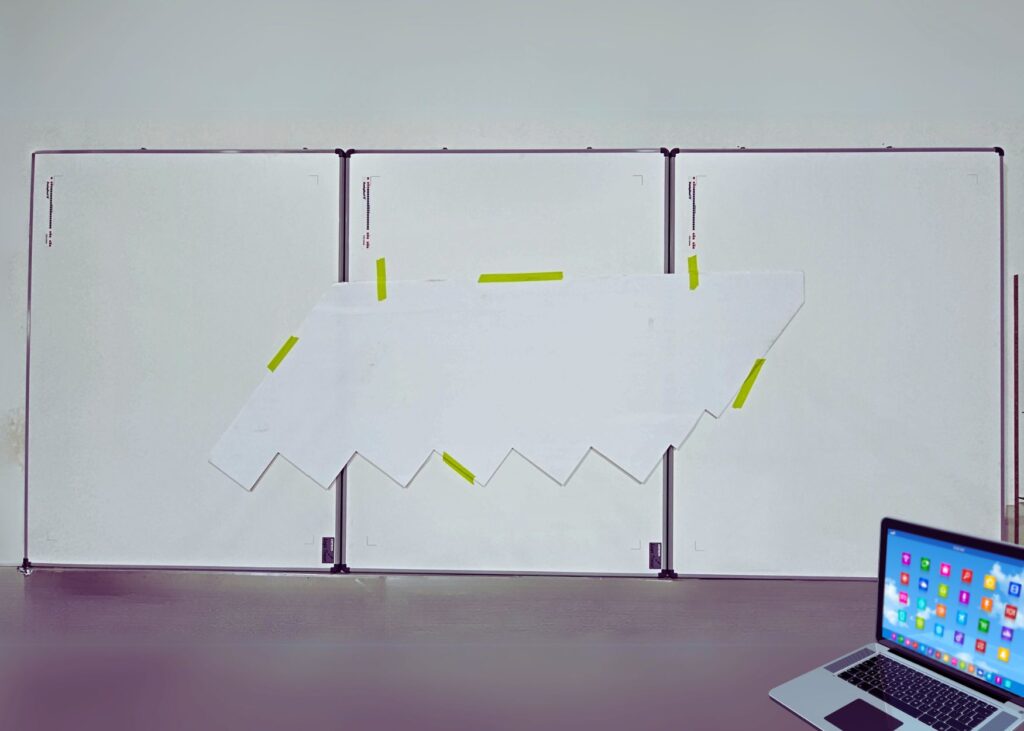

digital tracing boards

Digital tracing boards enable precise measurement of intricate shapes and create digital files that can be sent directly to CNC machines. They ensure accuracy, reduce errors, and save time by eliminating manual processes. This minimizes material waste and guarantees consistent, high-quality results, especially in applications like glass fabrication. A perfect blend of precision and efficiency!

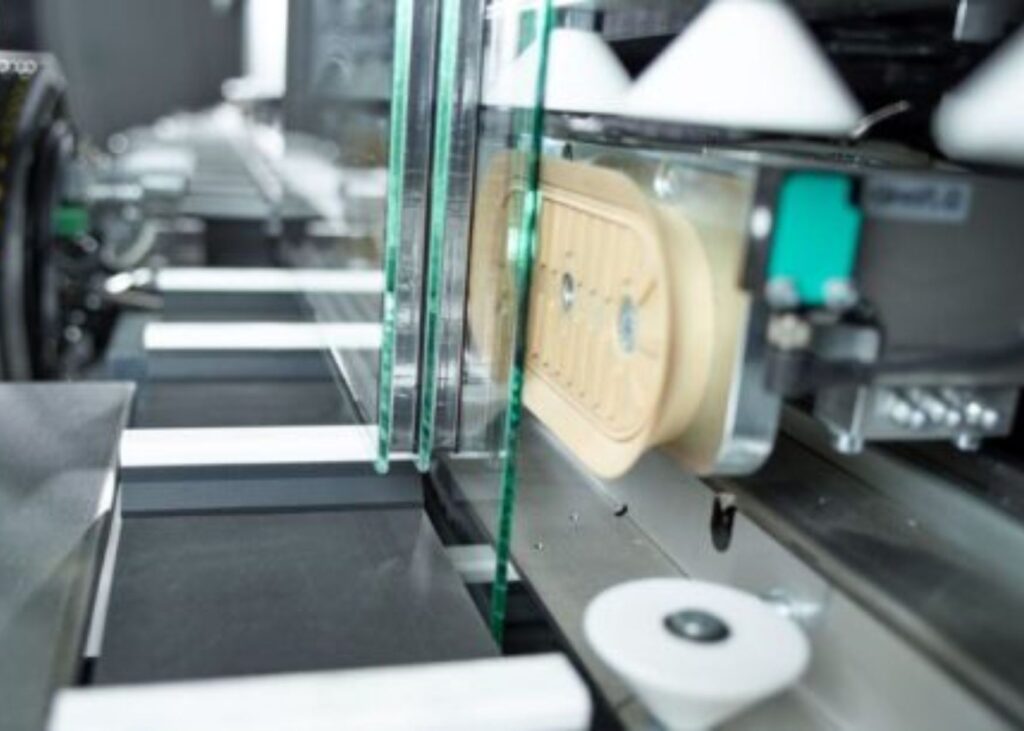

GLASS WAsHING STATION

A glass washing machine is an essential piece of equipment in the glass manufacturing process, designed to clean glass surfaces thoroughly before any further treatment, such as tempering or laminating. These machines use advanced cleaning mechanisms, including brushes, water sprays, and air blowers, to remove contaminants like dust, oils, and debris from the glass surface, ensuring it’s spotless and ready for processing.

Washing the glass before tempering is crucial because any impurities or residues on the surface can negatively affect the quality and durability of the finished product. Dirt or oil can create imperfections during the tempering process, leading to uneven heating and cooling, which might compromise the strength and safety of the tempered glass. By using a glass washing machine, manufacturers guarantee that the glass maintains its structural integrity, visual clarity, and optimal performance, delivering reliable and high-quality results for any application.